A key element in the material handling industry is the sizing of items within a warehouse environment, production facility or distribution centre. A major challenge constantly faced in the measuring industry is accurate sizing and high throughput. Measuring of goods can be very timeously with the risk of human error. However, we have developed completely stable solutions to these problems. Storage Management Systems employ intelligent, highly efficient algorithms that allow us to achieve incredible tolerances whilst maintaining rapid stock throughput.

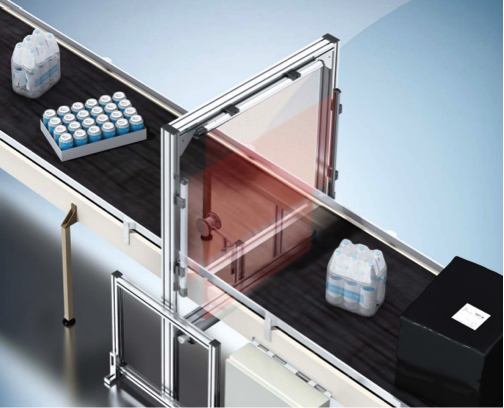

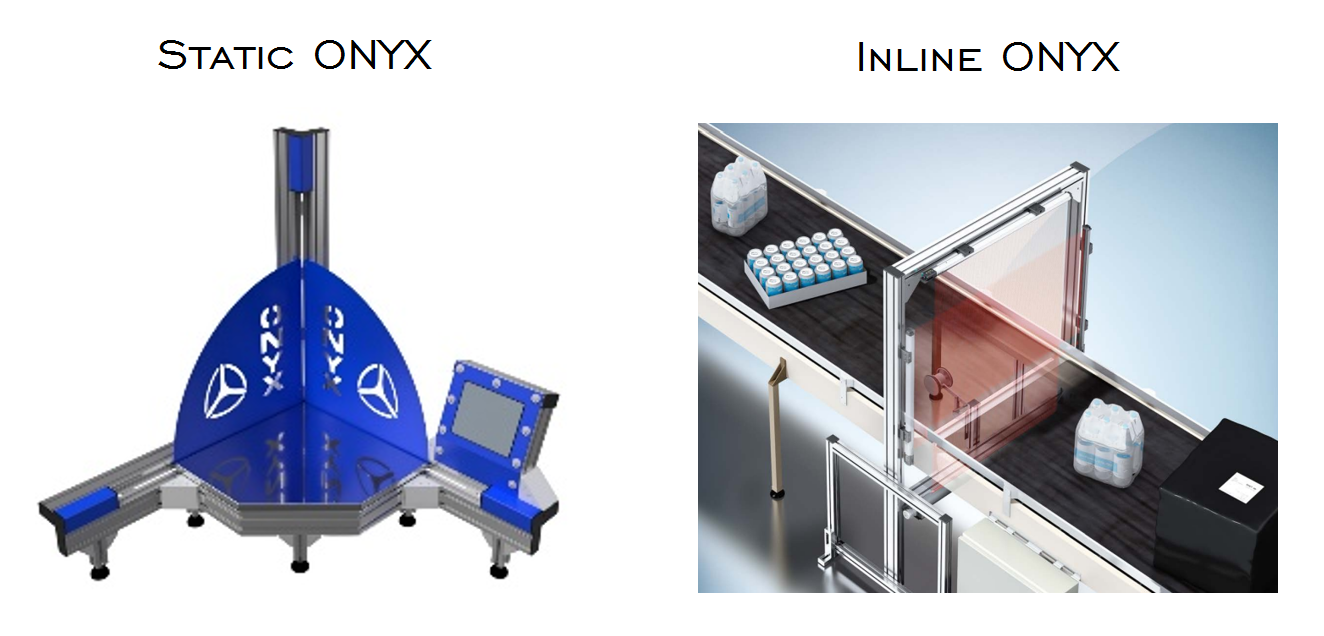

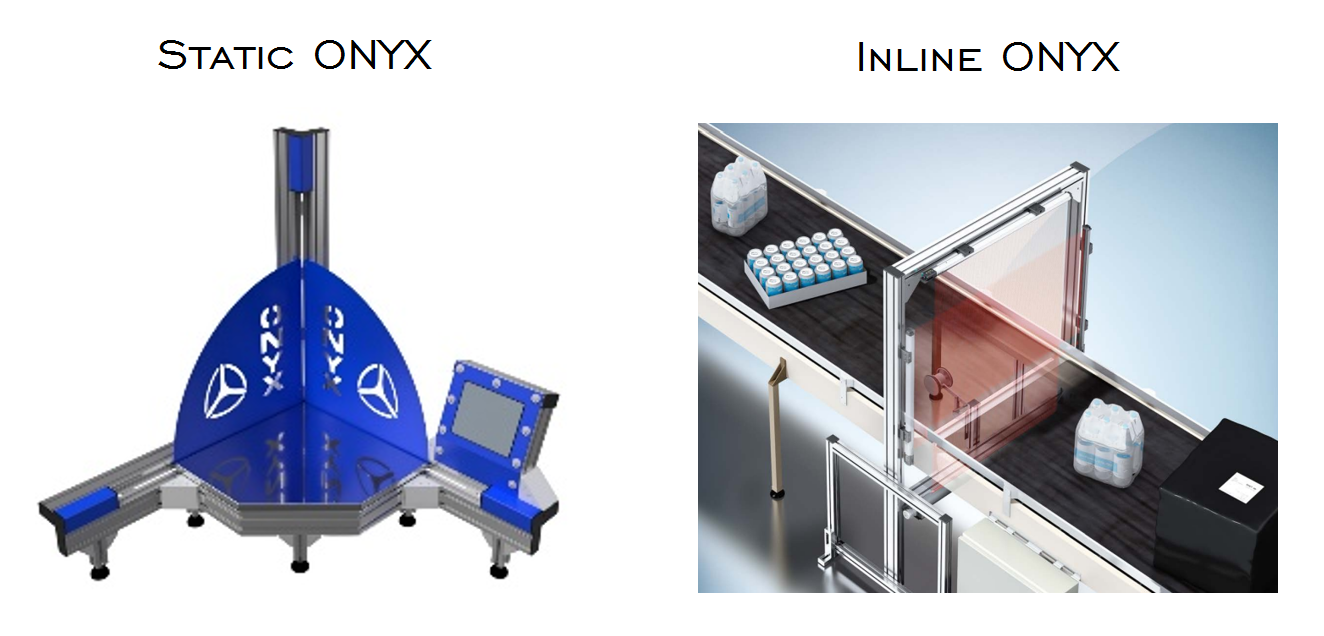

If throughput is not a concern, our static systems utilize high-grade laser equipment and completely natural interfaces to make the user experience not only simple but enjoyable too. Our ONYX system allows for an error free solution to your cubing and weight measurement challenges. The ONYX system seamlessly integrates into any Warehouse Management System, whereby dimensional weight information are uploaded to the Warehouse Management System. This integration eliminates human capturing errors, ensures dynamic and up-to-date data availability and improves storage planning which ultimately leads to better space utilisation. This is an essential tool for accurate freight manifesting. The quick volumetric weight checking allows for more reliable customer billing, as well as load planning.

Optional extras

- Barcode scanner

- Label printer

- Trolley for mobile option

- Historic data base for tracking & reporting purpose

- Different machine colours