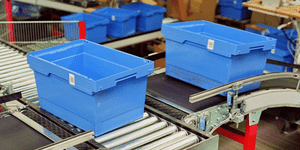

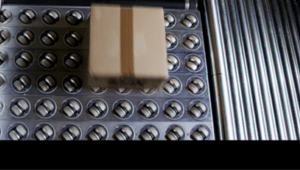

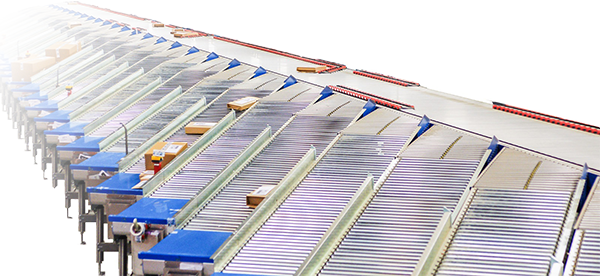

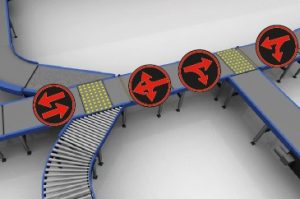

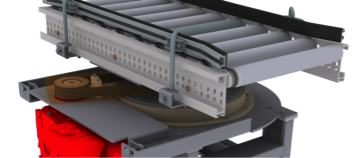

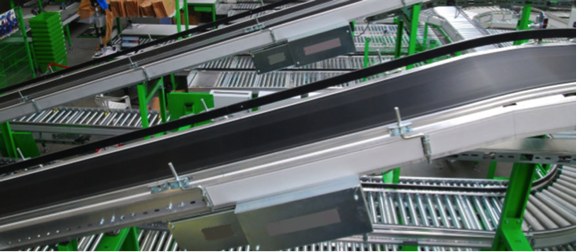

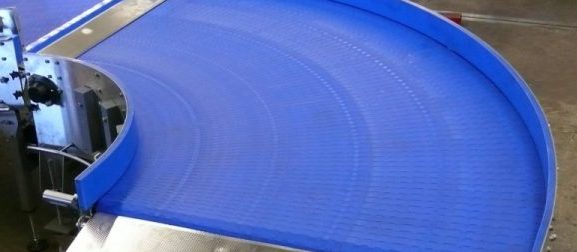

SMS offers an extensive range of unit material handling technologies to meet all the unit movement requirements of a wide variety of industries – from very high throughput parcel handling, as found in courier applications, right through to pharmaceutical distribution, FMCG and production warehouses.

We continuously take note of the rapid advances in a host of the following technologies and are confident in offering our clients the most innovative and state-of-the-art solutions, which ensure operational efficiency well into the future.